| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : YNF

Model Number : SD200N

Certifiion : CE

Place of Origin : China

MOQ : 1

Price : 30-80usd/piece

Payment Terms : T/T, Western Union, MoneyGram

Supply Ability : 3000pieces/week

Delivery Time : 2-3days after payment

Packaging Details : Neutral Package

Material : Natural Rubber

Part Name : Planet Carrier

Quality : High Guarantee

Outer Packing : Carton

Performance : Engine Power Transmission

Marketing Type : Ordinary Product

Mark : According to customer needs

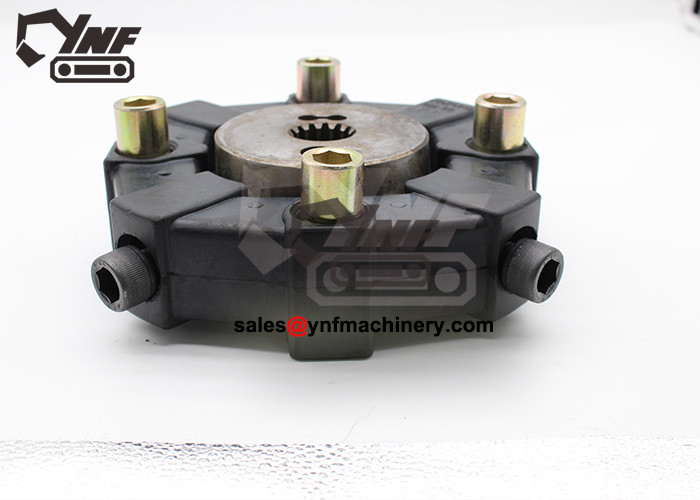

Excavator Rubber Coupling Hydraulic Pump Parts High Quality For SD200N

Description :

| Parts Name | Hydraulic Pump Coupling |

| Processing | Forging |

| Outer Packing | Carton |

| Delivery Methods | Express: DHL, FedEx, EMS, UPS or by Air/Sea |

| Place of Origin | China |

| Condition | OEM/Original |

| HS Code | 8483600090 |

| Inventory | In stock |

| Certifiion | CE |

Products Show:

Packaging & Delivery

| Packaging Details: | Plastic bag, Carton |

| Delivery Detail: | Within 3 workingdays after payment |

Coupling Information:

Couplings are also called couplings. A mechanical component used to firmly connect the driving shaft and the driven shaft in different mechanisms to rotate together and transmit motion and torque. Sometimes it is also used to connect shafts and other parts (such as gears, pulleys, etc.). It is often composed of two halves, which are respectively connected by keys or tight fittings, and are fastened at the ends of the two shafts, and then the two halves are connected in some way. The coupling can also compensate for the offset (including axial offset, radial offset, angular offset or comprehensive offset) between the two shafts due to inaccurate manufacturing and installation, deformation during operation or thermal expansion, etc. ; and shock mitigation and vibration absorption.

Most of the commonly used couplings have been standardized or standardized. Generally, it is only necessary to correctly select the type of coupling and determine the type and size of the coupling. When necessary, the load capacity can be checked and calculated for its vulnerable weak links; when the rotation speed is high, the centrifugal force of the outer edge and the deformation of the elastic element should be checked, and the balance check should be carried out.

Couplings can be divided into two egories: rigid couplings and flexible couplings.

Rigid couplings do not have buffering properties and the ability to compensate for the relative displacement of the two axes, requiring strict alignment of the two axes. , Easy maintenance, can ensure high neutrality of the two shafts, large transmission torque, and wide appliion. Commonly used are flange couplings, sleeve couplings and jacket couplings.

Flexible couplings can be divided into flexible couplings with no elastic elements and flexible couplings with elastic elements. The former type only has the ability to compensate for the relative displacement of the two axes, but it cannot buffer and reduce vibration. The common ones are slippery. Block couplings, gear couplings, universal couplings and chain couplings, etc.; the latter type contains elastic elements, in addition to the ability to compensate for the relative displacement of the two axes, it also has the functions of buffering and damping. However, due to the limitation of the strength of the elastic element, the transmitted torque is generally not as good as the flexible coupling without elastic element. The common elastic sleeve pin coupling, elastic pin coupling, plum-shaped coupling, tire type coupling Couplings, serpentine spring couplings and reed couplings, etc.

Guangzhou XIEBAGN MACHINERY CO., LIMTED

specialized in:

couplings, rubber mounts, gera parts, hydraulic seals and seal kits for hydraulic hammers, rock breakers, hydraulic excavators,wheel loaders, and JCB badkhoe loaders.

And, Our company also supply:

Engine parts, hydraulic piston pump and hydraulic travel motor, Swing motor assembly and hydraulic component parts, electric parts, etc. Hydraulic hammer breaker parts with piston, cylinder, chisel, through bolt, side bolt, top bush, front head bushing,accumlator, valve, etc.

We always try our best for all our customers and make it better and better. Welcome!

|

|

Planet Carrier Excavator Rubber Coupling Hydraulic Pump Parts For SD200N Images |